Modding a GBC Laminator

Folder: Electronics

I was trying to get toner transfer to work with a laminator and toner transfer paper. I failed...

12 Aug 2008

pulsarprofx toner transfer: test 01

my first test of the toner-transfer method using the pulsarprofx paper and a simple clothes iron.

12 Aug 2008

pulsarprofx toner transfer: test 02

pulsarprofx toner transfer test. lack of pressure. details are ok, but toner does not stick properly to aluminum board.

12 Aug 2008

pulsarprofx toner transfer: test 03

pulsarprofx toner transfer test. using pulsar's suggested method using a piece of round wood to increase pressure of the iron. sticks like mad, cannot be scratched away but the details are gone. all smudged.

18 Aug 2008

Modding the GBC H212 Laminator for THICK stuff (PCBs)

Some plastic parts (paper guides) kept 1.5mm PCBs (64mil) from passing through the laminator and just broke off. The fusing drums don't mind the thickness, all is springloaded. So the plastic buggers had to go...

18 Aug 2008

Closeup on the plastic parts that need to be removed

Closeup on the plastic guides (white part) that had to be removed. Just unscrew the screw, remove, rescrew the screw :-)

18 Aug 2008

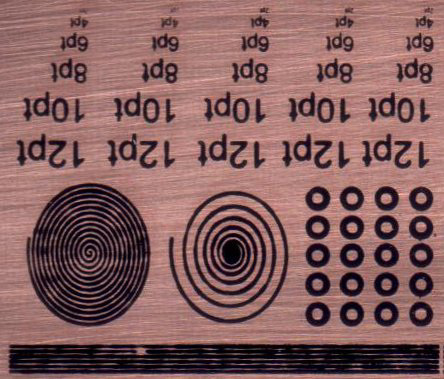

Toner transfer test with laminator - closeup

Closeup on the first tests with the pulsar toner transfer paper and my new GBC H212 laminator. I'm not quite happy with it. The lines + spacing are 0.25mm and I had to run it through the laminator about 15 times. I'm starting to doubt whether toner transfer is such a big saver of time/work compared to the usual photographic transfer. OK more chemicals involved, but NaOH doesn't stink and is much cheaper than a laminator and with the right UV box, it's painless and gives 100% result.

18 Aug 2008

Toner transfer test with laminator

The first test of toner transfer with my new laminator - hating it already :-(

Sounded much easier on the websites I checked. Maybe I'll buy a UV box for photographic transfer _again_ ... too bad I sold my old one some time ago :-(

Anybody want a laminator ? (I don't pay for shipping of course). Maybe this is just jocular

11 Sep 2008

GBC-H212 - 25k_pot

25k pot in series with the ntc. adding 1.9k was enough to bring the drums from about 130°C to 170°C. the toner transfer paper stuck much better to the PCB, but the results were still poor. and the laminator stinks even worse at higher temperatures. should only be used outside of buildings. can't imagine how people tolerate that odor in offices.

NO MORE TONER TRANSFER.

Jump to top

RSS feed- Latest items - Subscribe to the latest items added to this album

- ipernity © 2007-2025

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

Twitter