Tudor brick

Waterworks railway

Mine No.1

Butterton

The Bulkeley boilers

Heaton sunset

Broadbent crushers

QJ 7049

Redacre Pit

For Sale

Apedale shed

Approaching the Guyaozi brickworks

Hale beasty

Rocksavage chemical plant

Mining Nanpiao style

Holman Brothers

Wooden hoppers to the colliery

Pick your own

Mule on cage

The perils of the wind

Lafarge Cauldon

Clive Brothers, Sandyford

SY 2008 morning passenger

Shutlingsloe from Bakestonedale

Marmion Shaft

Mouth of tunnel

Lambton Colliery 1936

Steam in the dunes

Apesford in the rain

Mushrooms?

Tissington

Fuli Mine

Limestone line

Crown Buildings, Crosby

Evening return

Limekiln at Hoften's Cross

Loznica Viscose

Birkhill Fireclay Mine

Burwood Colliery

SY 0804 leaving Lijing Mine

Penuel

Desert empties

Pleasure boating

Dalong Mine

Birkby Wyke

Location

Lat, Lng:

You can copy the above to your favourite mapping app.

Address: unknown

You can copy the above to your favourite mapping app.

Address: unknown

Keywords

Authorizations, license

-

Visible by: Everyone -

All rights reserved

-

463 visits

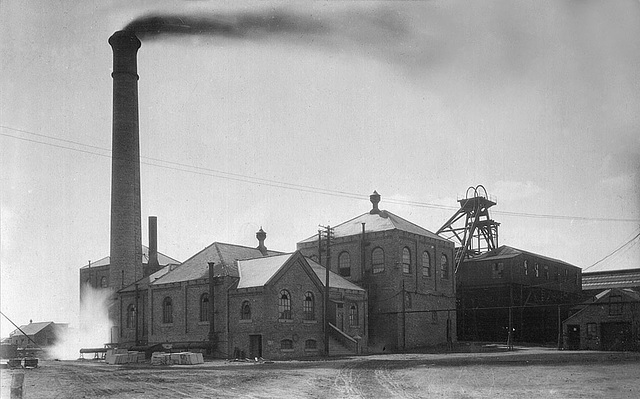

Ellington Colliery

This colliery, which before nationalisation was owned by Ashington Coal Co. Ltd., commenced operations in 1910, and the take is now served by two downcast shafts, one upcast shaft and a man-access drift. Of these, the main coal-winding shaft is No. 1, which is downcast, 13 ft. in dia. and 425 ft. deep to the Yard seam level. The other downcast is also 13 ft. in dia. but the upcast (No. 3) has a diameter of 15 ft. No. 2 shaft is sunk to the Five Quarter seam level with its winding inset at the Yard seam level where in addition to being used for manriding it deals with that fraction of the output with which the No. 1 shaft is unable to cope in two shifts’ winding. The No. 3 shaft is 548 ft. deep to the Five Quarter seam and is equipped with a single-deck cage suitable for relief manriding only.

Both the downcast shafts have doubledeck cages which carry two 10½-cwt. tubs on each deck. They are equipped with rail-type rigid guides, and No. 1 pit winding rope has a circumference of 4½ in. which is a quarter of an inch greater than the circumference of No. 2 pit winding rope. Steam winding is practised at both these shafts, the engines, which are of Robey manufacture, having cylinders of 20-in bore and 40-in stroke. Each winder is fitted with Black brakes and has a cylindrical drum 9 ft. dia. by 6 ft. wide.

Ellington has a severe water problem, as much as one million and twenty thousand gallons being pumped out of the pit daily, and we understand that at one time there was at least three tons of water raised for every ton of coal wound.

Information from Colliery Engineering Magazine via the Durham Mining Museum website.

Both the downcast shafts have doubledeck cages which carry two 10½-cwt. tubs on each deck. They are equipped with rail-type rigid guides, and No. 1 pit winding rope has a circumference of 4½ in. which is a quarter of an inch greater than the circumference of No. 2 pit winding rope. Steam winding is practised at both these shafts, the engines, which are of Robey manufacture, having cylinders of 20-in bore and 40-in stroke. Each winder is fitted with Black brakes and has a cylindrical drum 9 ft. dia. by 6 ft. wide.

Ellington has a severe water problem, as much as one million and twenty thousand gallons being pumped out of the pit daily, and we understand that at one time there was at least three tons of water raised for every ton of coal wound.

Information from Colliery Engineering Magazine via the Durham Mining Museum website.

- Keyboard shortcuts:

Jump to top

RSS feed- Latest comments - Subscribe to the comment feeds of this photo

- ipernity © 2007-2025

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

Twitter

Sign-in to write a comment.